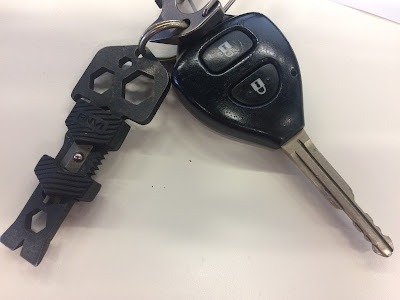

It's no secret that I am a big fan of keychain tools. I've covered dozens over the years, and there are a number secreted away within my EDC, much to the chagrin of airport security and delight of random "I broke my widget" people of the workplace and dinner party alike.

I keep an eye on the Kickstarter "tools" posts and cool-tool sites alike. The SKey is neat little tool that is jam packed with features. This is the new and improved version, in titanium. Yay Titanium. From top to bottom: a Key ring hole.

A very fine hole, just wide enough to feed a split-ring through. Wrench holes. I got the Metric system version which was 4mm, 8mm and 10mm sized holes, the Imperial system version has 14/4" and 5/16" openings. Bottle Opener. what pocket tool would be complete with out the generally supplanted bottle-cap opener. I usually drink screw-caped drinks, but its always good to be the hero and pop a budddies beer-bottle when they've a need. Saw-blade. A set of 13 straight-cut teeth with no fleam this make for a limited rip-saw action, but it'll do in a pinch where you need to saw rather than cut or chop.

Two-head screw bit: secured in the center of the tool in a gap cut into through the center is 1/4" tool bit, with a flat head driver at one end and a chunky Phillips head at the other. The supplied bit is 32mm long, so swapping it out with your own bits of comparable length should be possible. New silicone band: From heir last campaign's version feedback, they learned that it was very hard to keep the bit in place by manufacturing precision alone. The bit is either too tight or too loose. So they developed the new silicone band to keep the bit secure, the band doesn't get in the way while opening bottle or other functions.

Its easy to slip off to make full use of the saw as needed and the bit pops right out. Screw driver hole: Paired with our two-head screw bit, Skey can be used as screw driver with this 1/4" socket. The bit has a ball-bearing detente to keep it in positive fitting and the sKey body adds quite a bit of torque. Box opener: They "pointy end" of the sKey can be used as box opener and works like a charm. The broad chisel end not only acts as a scraper, and a flathead screw-driver, as well as turning the entire tool into a functional, if small, pry-bar. Wire peeler: in the middle of the Skey box-opener end is a notch designed to work as a wire stripper is quite handy for simple electrical device repairing. The deep, sharp sided notch is perfect for stripping quite fine wires.

Its easy to slip off to make full use of the saw as needed and the bit pops right out. Screw driver hole: Paired with our two-head screw bit, Skey can be used as screw driver with this 1/4" socket. The bit has a ball-bearing detente to keep it in positive fitting and the sKey body adds quite a bit of torque. Box opener: They "pointy end" of the sKey can be used as box opener and works like a charm. The broad chisel end not only acts as a scraper, and a flathead screw-driver, as well as turning the entire tool into a functional, if small, pry-bar. Wire peeler: in the middle of the Skey box-opener end is a notch designed to work as a wire stripper is quite handy for simple electrical device repairing. The deep, sharp sided notch is perfect for stripping quite fine wires. It's a handy tool and is cutting edge free, keeping it out of the grabby hands of most Eagle-eyed airport security guards.

https://www.kickstarter.com/projects/35126180/skey-key-shaped-titanium-multi-tool-now-in-black